Κερί παραφίνης

Introduction:

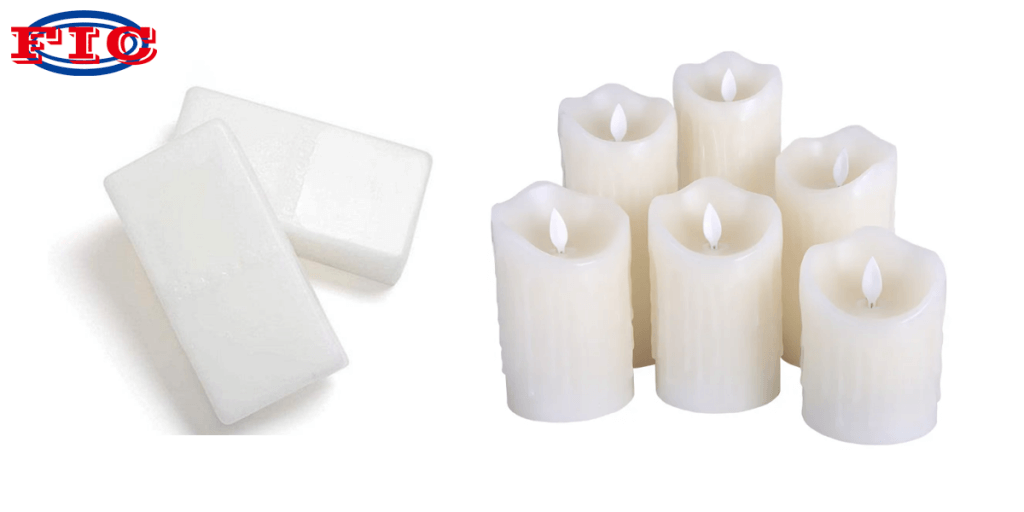

Paraffin wax is a colorless or white, soft, solid wax that is derived from petroleum. It is a mixture of long-chain hydrocarbons, primarily of the straight-chain alkane series. It is one of the most commonly used waxes in the world and is widely used in various industries for its numerous benefits. Paraffin wax is typically produced by refining crude oil or petroleum. The crude oil is heated to separate the different components based on their boiling points. The paraffin wax is then separated from the other components using various techniques, such as solvent extraction or distillation.

CAS No. 8002-74-2

Molecular Formula/MF CnH2n+2

HS Code 271220000

Classification petroleum chemical

Classification:

Paraffin wax can be classified into two categories based on the melting point. The first category is low-melting point paraffin wax, which has a melting point of around 50-60°C. The second category is high-melting point paraffin wax, which has a melting point of around 60-70°C. The low-melting point paraffin wax is used in industries that require a low melting point, such as cosmetics, while the high-melting point paraffin wax is used in industries that require a high melting point, such as candle making.

Advantages:

Paraffin wax has numerous advantages that make it a popular choice in various industries. Some of the advantages are:

Low cost: Paraffin wax is a low-cost material compared to other waxes, making it an attractive option for industries that require large quantities of wax.

Colorless and odorless: Paraffin wax is a colorless and odorless material, which makes it ideal for use in industries that require a neutral or natural appearance, such as cosmetics.

Good thermal conductivity: Paraffin wax has good thermal conductivity, which makes it an ideal material for use in industries that require heat transfer, such as in the manufacturing of candles.

Easy to handle: Paraffin wax is a solid material at room temperature, making it easy to handle and transport.

Versatile: Paraffin wax can be easily blended with other waxes and materials to create custom formulations for specific applications.

Industrial Use:

Paraffin wax is widely used in various industries due to its numerous advantages. Some of the industrial uses of paraffin wax are:

Candle making: Paraffin wax is the most commonly used wax in the manufacturing of candles. It is used due to its low cost, ease of use, and ability to hold fragrance and color.

Cosmetics: Paraffin wax is used in the manufacturing of cosmetics such as lipsticks, creams, and lotions. It is used as a thickening agent and to create a smooth texture.

Food industry: Paraffin wax is used in the food industry as a coating for fruits and vegetables to improve their appearance and increase their shelf life.

Pharmaceuticals: Paraffin wax is used in the manufacturing of various pharmaceutical products such as ointments, creams, and suppositories.

Packaging industry: Paraffin wax is used in the packaging industry as a coating for paper and cardboard to improve their water resistance and durability.

Rubber industry: Paraffin wax is used in the rubber industry to reduce the tackiness of rubber products. Rubber and Tires as mould release agents, plasticizers and lubricants in rubber blends

Paper industry: Paraffin wax is used in the paper industry to improve the water resistance and strength of paper products.

Textile industry: Paraffin wax is used in the textile industry as a sizing agent to improve the appearance and texture of fabrics.

Electrical industry: Paraffin wax is used in the electrical industry as an insulator for electrical components.

Agriculture industry: Paraffin wax is used in the agriculture industry as a coating for seeds to improve their germination and protect them from pests.

In addition to these industries, paraffin wax is also used in various other applications, such as in the production of crayons, inks, and lubricants.

Conclusion:

Paraffin wax is a versatile material that has numerous advantages, including low cost, colorless and odorless appearance, good thermal conductivity, and ease of handling. It is widely used in various industries such as candle making, cosmetics, food, pharmaceuticals, and packaging. Its ability to be easily blended with other materials to create custom formulations makes it a popular choice in industries that require specific properties.

With a robust production capability and effective supply chain management, we can meet market needs. Producing over 13,000 tons each year, we serve both small sample inquiries and big bulk demands. Our focus is on customer contentment, aiming to create lasting relationships and shared progress. We aim to achieve ongoing improvement and excellent assistance, driving mutual growth and achievement.

Our products meet the highest industry standards, ensuring reliability. We prioritize satisfaction with personalized services and excellent support.